E-TRO

01

Electrical RTO design technology and system configuration- The odor reducer FA series is designed with a dual structure of RTO and RCO that promotes oxidation and decomposition of odor-causing substances in high -temperature combustion furnaces and catalyzes decomposition with catalysts. It has overcome the weaknesses of RCO, increased decomposition efficiency, reduced energy, and was designed to be suitable for dealing with various complex odors.

- Characteristics

- Reaction Mechanism : FA-RTO oxidizes/decomposes odour-causing substances in electrical high temperature combustion furnaces, while typical VOC and composite odors are oxidized around 400 to 850℃. It is a structure that uses platinum, palladium, and radium catalysts to perform secondary oxidation/ decomposition by mounting an RCO function for the treatment of some turbulent substances.

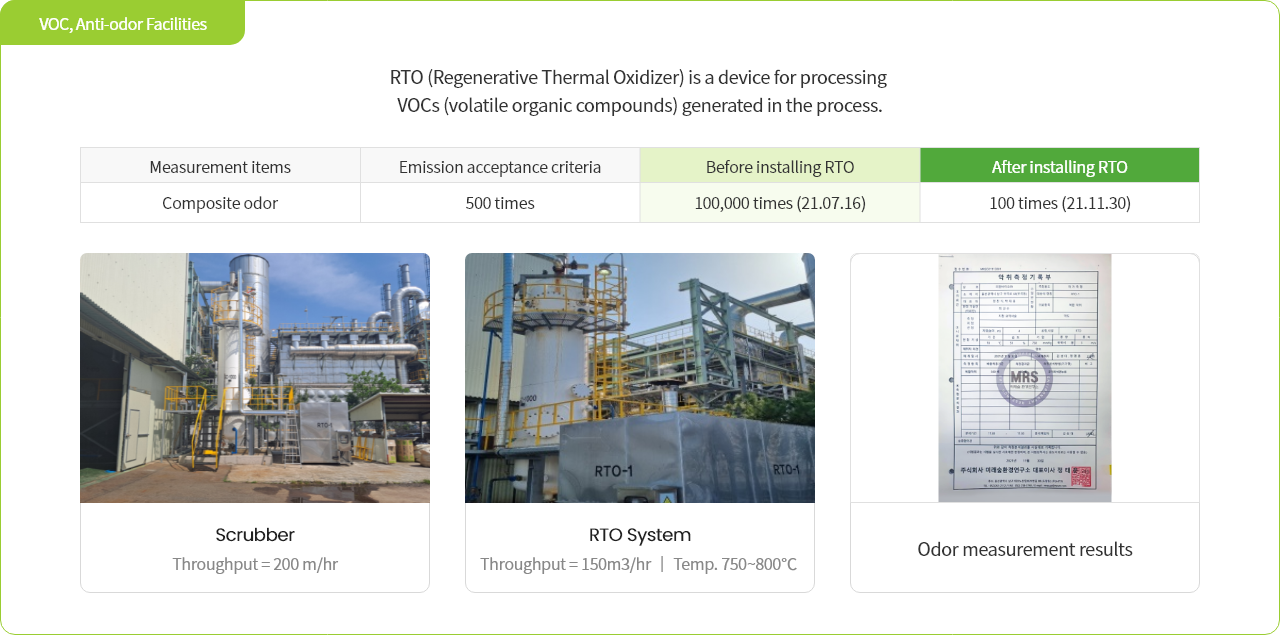

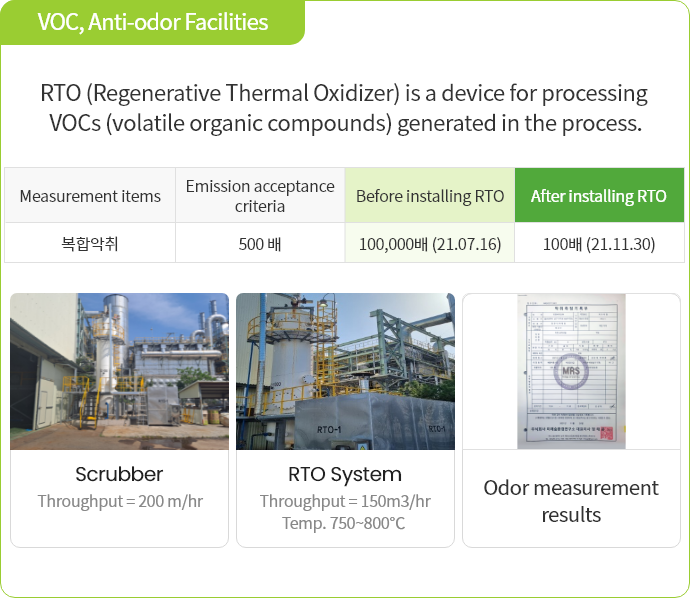

- Installation Examples

02

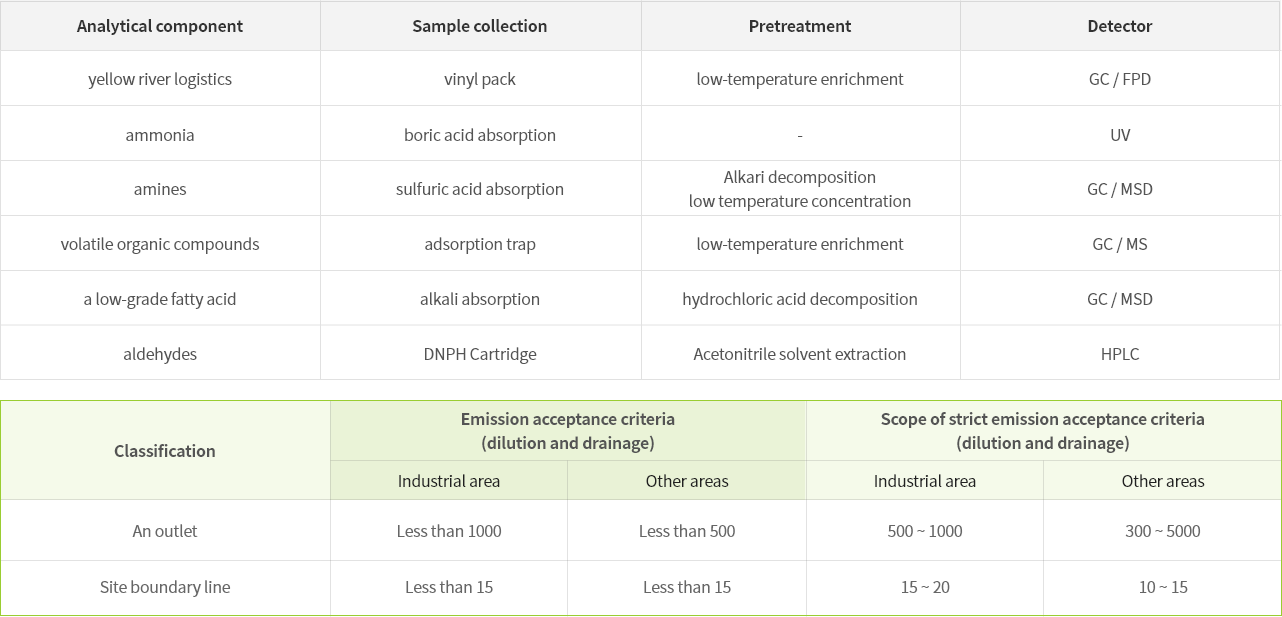

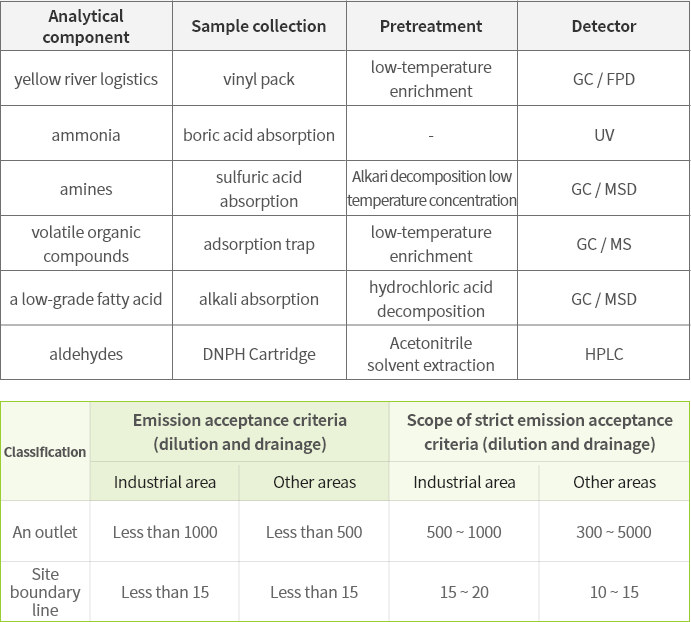

Catalyst Technology Field For Compound Odor And Special Odor Substances- Odor Process Test Method (Equipment Analysis)

- It is the result of analyzing odors generated when treating food waste, and it is possible to reduce odors for 6 causative substances such as complex odors and ammonia.

-

- Treatment Plan

-

① Elimination of odors by diversification of catalysts

② Improvement of Current Disadvantages of Gas Combustion (Problems due to Condensed Water)

③ Analysis of the cause of failure of rotor type during waste heat recovery

-

- Solution plan

-

① Development of Multi-Catalyst Zones that can respond to various odor-causing ingredients

② Adopt Electrical heating and waste heat recovery methods

③ Achieve minimal maintenance costs

03

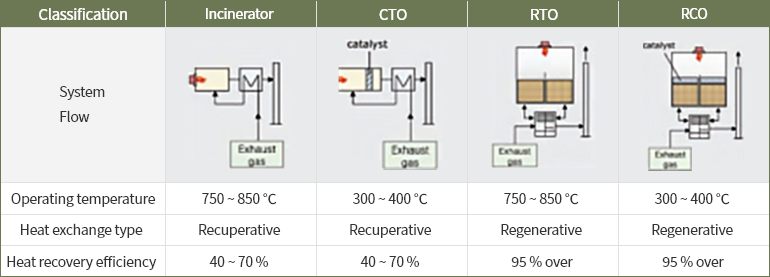

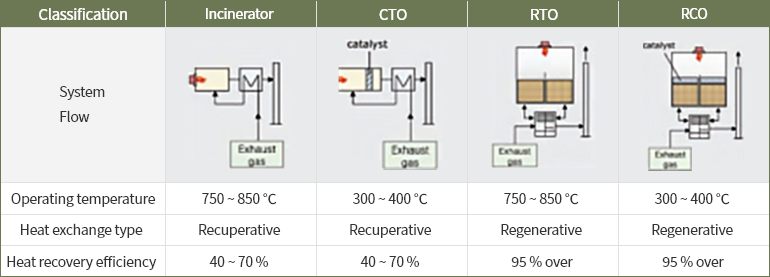

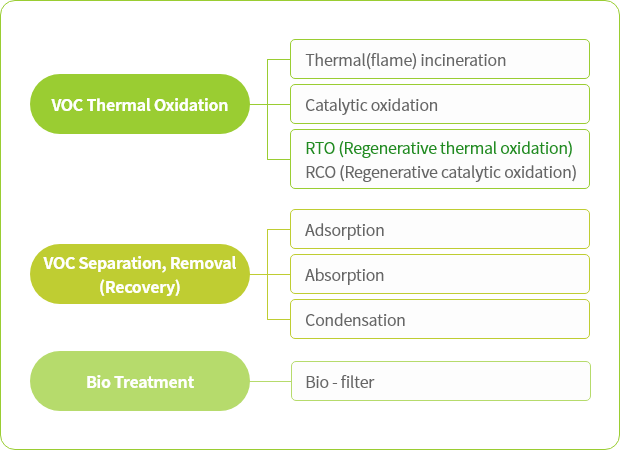

Construction of Odor Removal Facilities and Operation Technology Field- Types of Voc Removal Facilities

- Comparison of Voc Removal Facilities