Negative Waste Oil

01

Production and System Installation of Negative Waste Oil through Operationand Management of Negative Waste Water

- Negative Waste Water, which approximately accounts for more than 70% of the total weight of food waste,

contains about 1-2% oil, and there are many technical methods for separating it. - Methods for recovering oil include thermal methods using heat and three-phase centrifugation methods using physical properties.

- It consists of a refining tank for purifying the separated oil and a shipping tank for storing the separated oil by precipitation.

- It is a Facilitiy consisting of a transfer pump for transferring negative waste water, a three-phase centrifuge (sludge, moisture, oil), purification and product tanks.

- The functional relationship between the rotational volume of a high-speed three-phase centrifuge and the nature of the sludge reflects the operator's

know-how (considering the field situation).

02

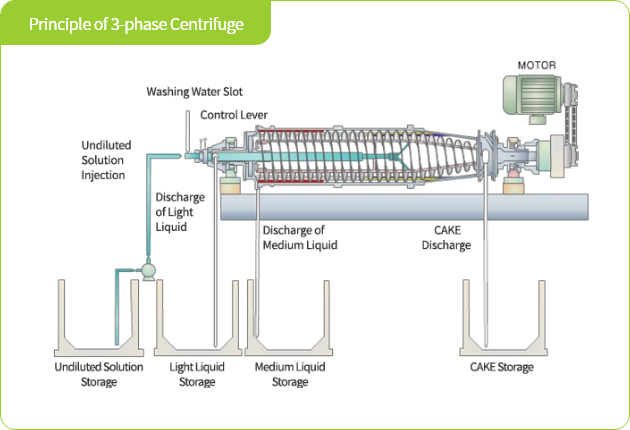

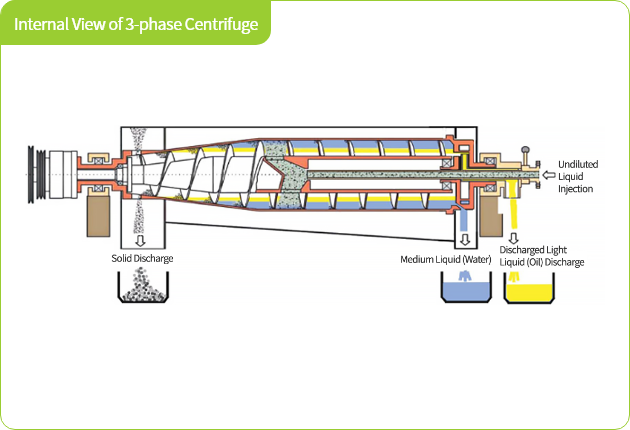

Three-phase Centrifuge and Refining Tank System Operational Field- Principle of 3-phase centrifuge : The centrifuge not only cleans solid-containing liquids, but also separates liquid mixtures of oil and water, into oil and water, respectively. When undiluted solution is introduced from the undiluted reservoir into the rotating body bowl through the injection tube, the undiluted solution is separated into physical specific layers by centrifugal force. The principle is that the solid is separated into layers in the bowl, the heavy liquid in the first layer, medium liquid in the second and light liquid in the third layer. After the separation process, the heavy liquid is discharged by a screw by the three-phase decant structure system, and the medium liquid and the light liquid are separated by theeccentricity control dam.

- Specifications for the Installation Model

| Model | Normal Flow Rate (㎡/hr) | Max. Speed (rpm) | Max. Centrifugal Force(g) | Motor Power (kW) | Dimension (L x W x H(m)) | Total Weight (ton) |

|---|---|---|---|---|---|---|

| BS250T | 0.8~1 | 4,600 | 3,000 | 7.5 | 1.8 x 1.0 x 1.5 | 0.9 |

| BS250TL | 1.5~2 | 4,600 | 3,000 | 11 | 1.8 x 1.0 x 1.5 | 1.0 |

| BS350T | 2~2.5 | 3,800 | 3,000 | 15 | 2.4 x 1.2 x 1.3 | 1.8 |

| BS350TL | 3.5~4 | 3,800 | 3,000 | 18.5 | 2.4 x 1.2 x 1.3 | 2.0 |

| BS420T | 4~5 | 3,300 | 3,000 | 30 | 3.1 x 1.5 x 1.3 | 3.9 |

| BS500TL | 8~10 | 2,800 | 3,000 | 37 | 3.3 x 1.8 x 2.1 | 4.5 |

| BS506TLL | 10~12 | 2,800 | 3,000 | 45(15) | 3.7 x 1.6 x 2.0 | 5.3 |

| BS507TLL | 12~15 | 2,800 | 3,000 | 55(18.5) | 3.8 x 1.6 x 2.1 | 5.6 |

03

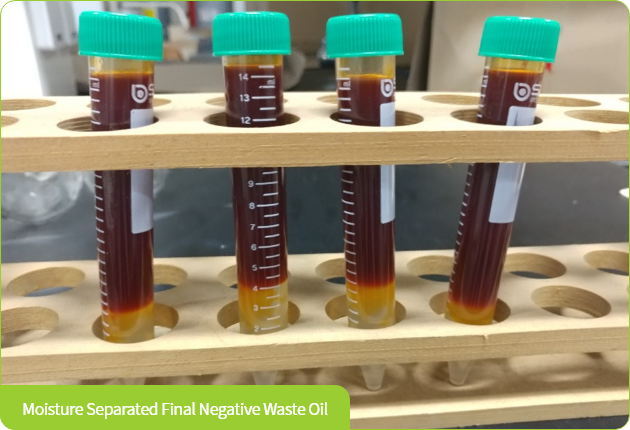

Refining and Recovery Operations of Negative Waste Oil- Analysis of oil is very important because negative waste oil varies greatly depending on the season and place of production.

- For this reason, we want to optimize the operation efficiency of the facility by checking the sludge and moisture content through

oil analysis and giving feedback to the field workers. - By heating the oil collected by the sample in the daily inspection, a simple field test is possible, and when passing it,

the normal operation of the oil separation facility can be confirmed, and the waste oil is transferred to the storage tank. - It is possible to produce a certain level of waste oil by analyzing the performance of oil produced by local governments through

centrifuges provided in our research institute.

- Example of Component Analysis Data

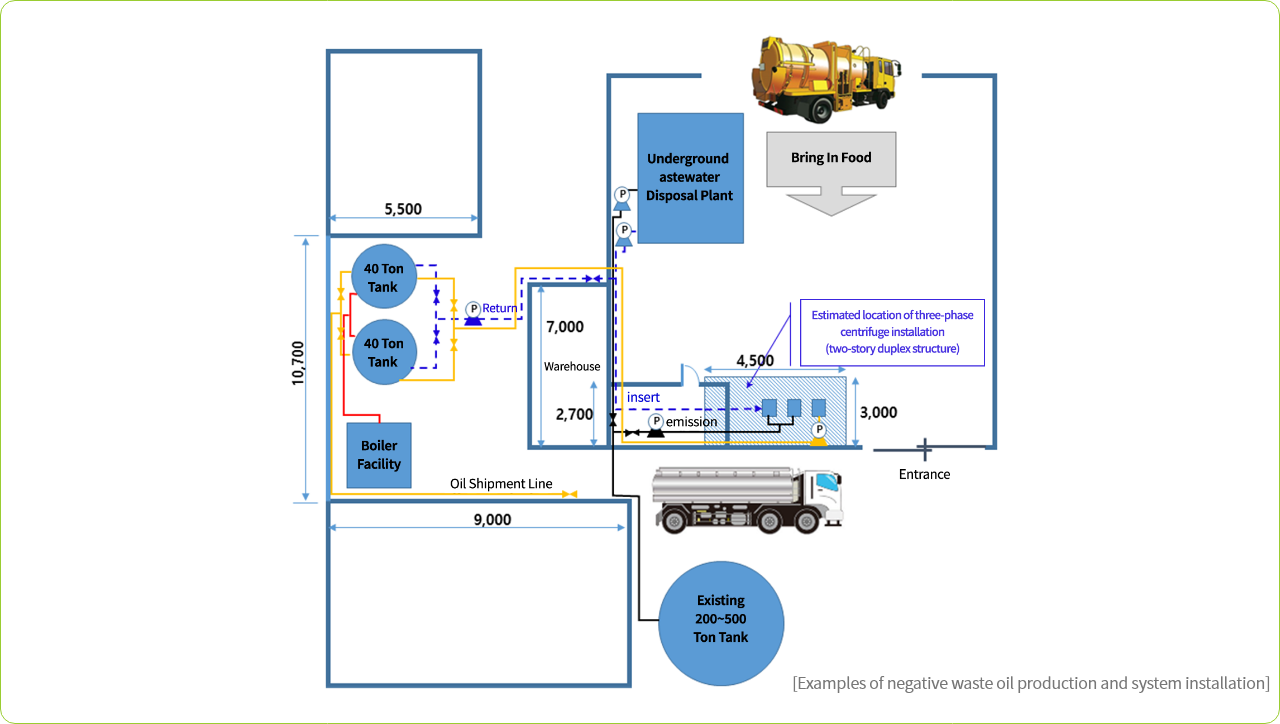

- The oil separation facility consists of a high-liquid separator, a three-phase centrifuge, two sets of auxiliary tanks, a storage tank (40 tons) and a wastewater tank.

- Assuming that the negative waste water generated in the process of treating food waste is about 50 tons per day, it is transferred to an oil separation facility,

and the sludge and negative waste water are first separated in a high-liquid separator by a pretreatment process, and the following process is performed. - The oil is separated into sludge, negative waste water and oil through a three-phase centrifuge (5∽6 tons per hour) and transferred to an auxiliary storage

tank with a heater. - After separated from water by heat in the auxiliary tank, only oil is stored in the storage tank.

- The production of negative waste oil varies by season, but the average daily production is expected to be approximately 1 ton per day.